1. First perform edge preparation on the pieces to be welded.

2. Clamp the two pieces in proper fixture else in absence of fixture perform tack welding at two end.

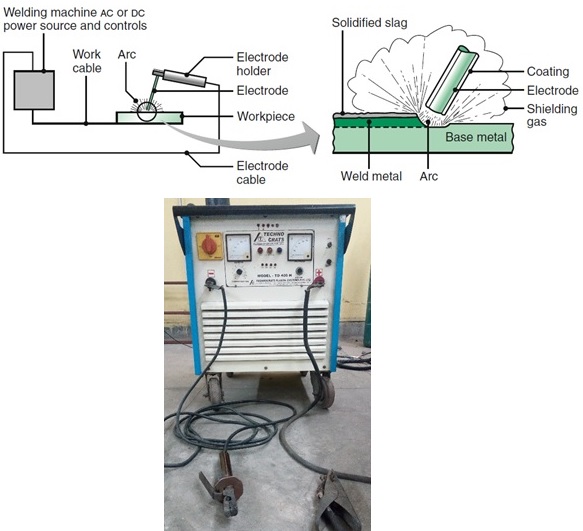

3. Now take an appropriate welding rod and set the welding current according to it.

4. Now connect the clamp with the work table first to get the power connection from the machine.

5. Next fix the electrode in holder and keep it vertically just above the parts to be welded.

6. Now touch the electrode tip with the job piece momentarily to complete the electrical circuit facilitate

arc initiation and maintains a gap of <5 mm between the electrode and job for arc continuity.

7. Move the arc along the weld line till the completion of first bead.

8. After completion let it cool for a while and remove the solidified slag layer by chipping.

9. In case of multi pass welding perform the next welding only after cleaning the slag properly.

Precautions

Always use proper protective equipment while performing this process.

Make sure the clamping is proper with the worktable and got proper earth in.

Never touch partially used electrode and any job piece kept at worktable as they may be hot.

Edge preparation and face matching is necessary for a good penetration.