Tungsten inert gas (TIG) welding is one of the cleanest process.

In this process filler metal is supplied from a filler wire. As the tungsten electrode is not consumed in this operation, a

constant and stable arc gap is maintained at a constant current level. The filler metals are similar to the metals to be welded,

and flux is not used. The shielding gas is usually argon or helium (or a mixture of the two). Welding with GTAW may be done

without filler metals for example, in the welding of close-fit joints. Depending on the metals to be welded, the power supply is

either DC at 200 A or AC at 500 A. In general, AC is preferred for aluminum and magnesium, because the cleaning action of AC removes

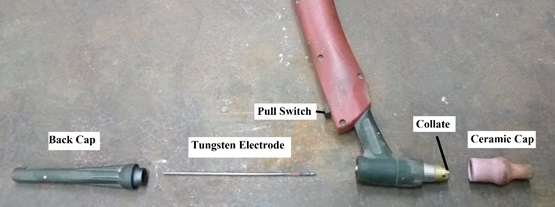

oxides and improves weld quality. Thorium or zirconium may be used in the tungsten electrodes to improve their electron emission characteristics.

The power supply ranges from 8 to 20 kW. Contamination of the tungsten electrode by the molten metal can be a significant problem, particularly

in critical applications, because it can cause discontinuities in the weld. Therefore, contact of the electrode with the molten-metal pool should be avoided.

The GTAW process is used for a wide variety of applications and metals, particularly aluminum, magnesium, titanium, and the refractory metals. It is

especially suitable for thin metals. The cost of the inert gas makes this process more expensive than MMAW, but provides welds of very high quality

and surface finish. GTAW is used in a variety of critical applications with a wide range of workpiece thicknesses and shapes.

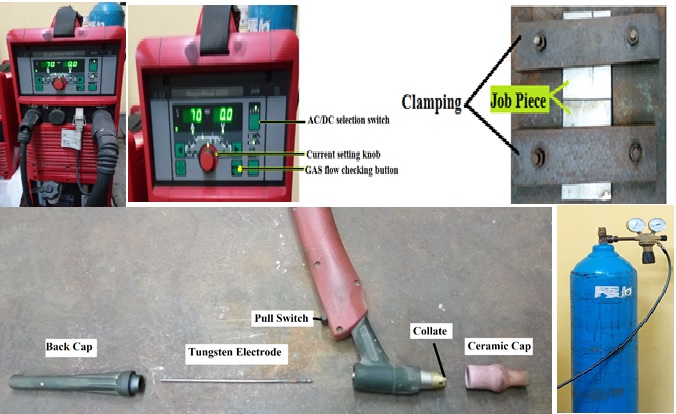

Model: Magic Wave 2500 TIG Welding Machine

Brand: Fronius

Model: Voltage: 220V

Model: Automatic Grade: Semi-Automatic

Model: Phase: 3 Phase

Model: Working voltage: 10.1-20.0 V